OUTSTANDING ADVANTAGES

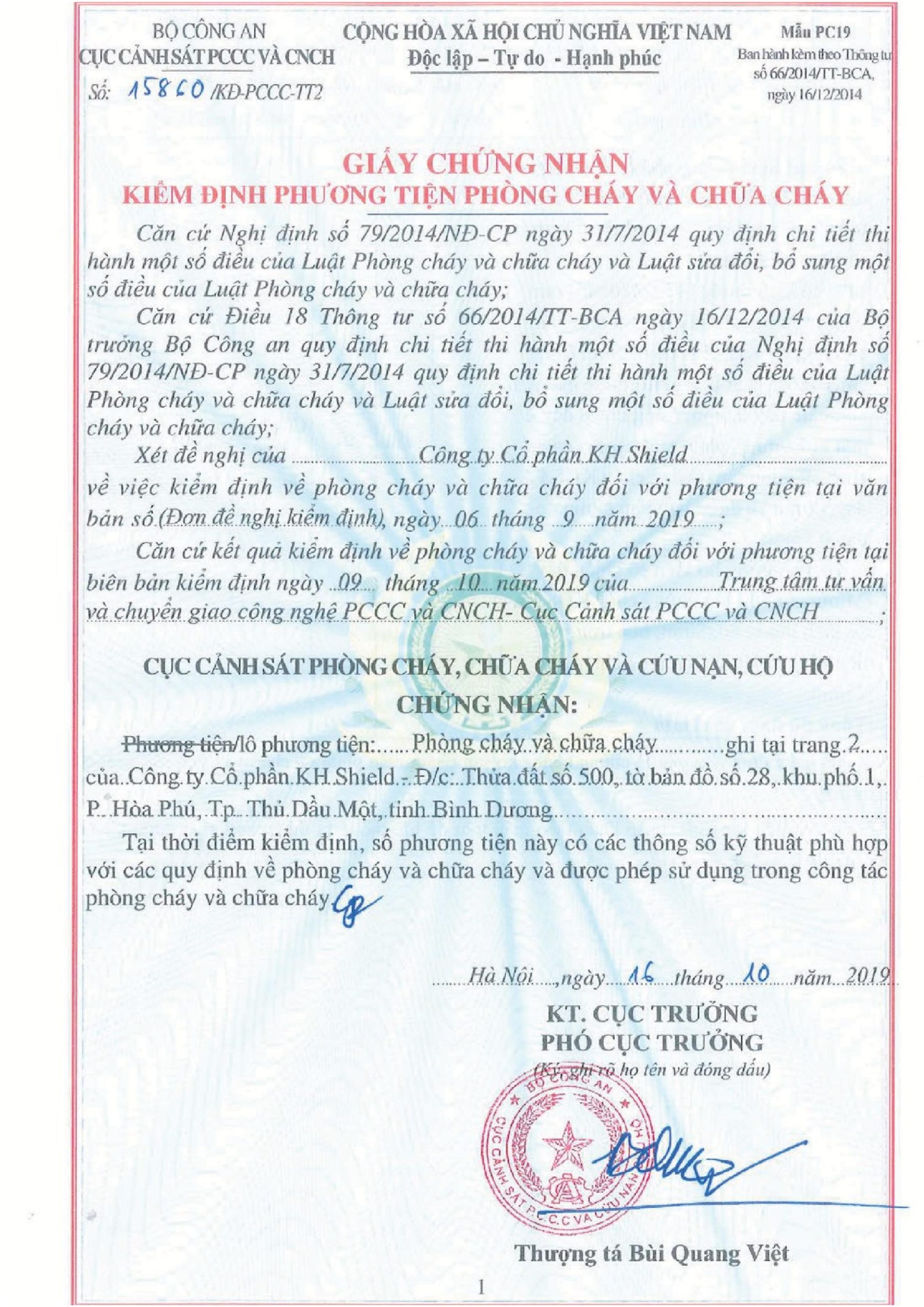

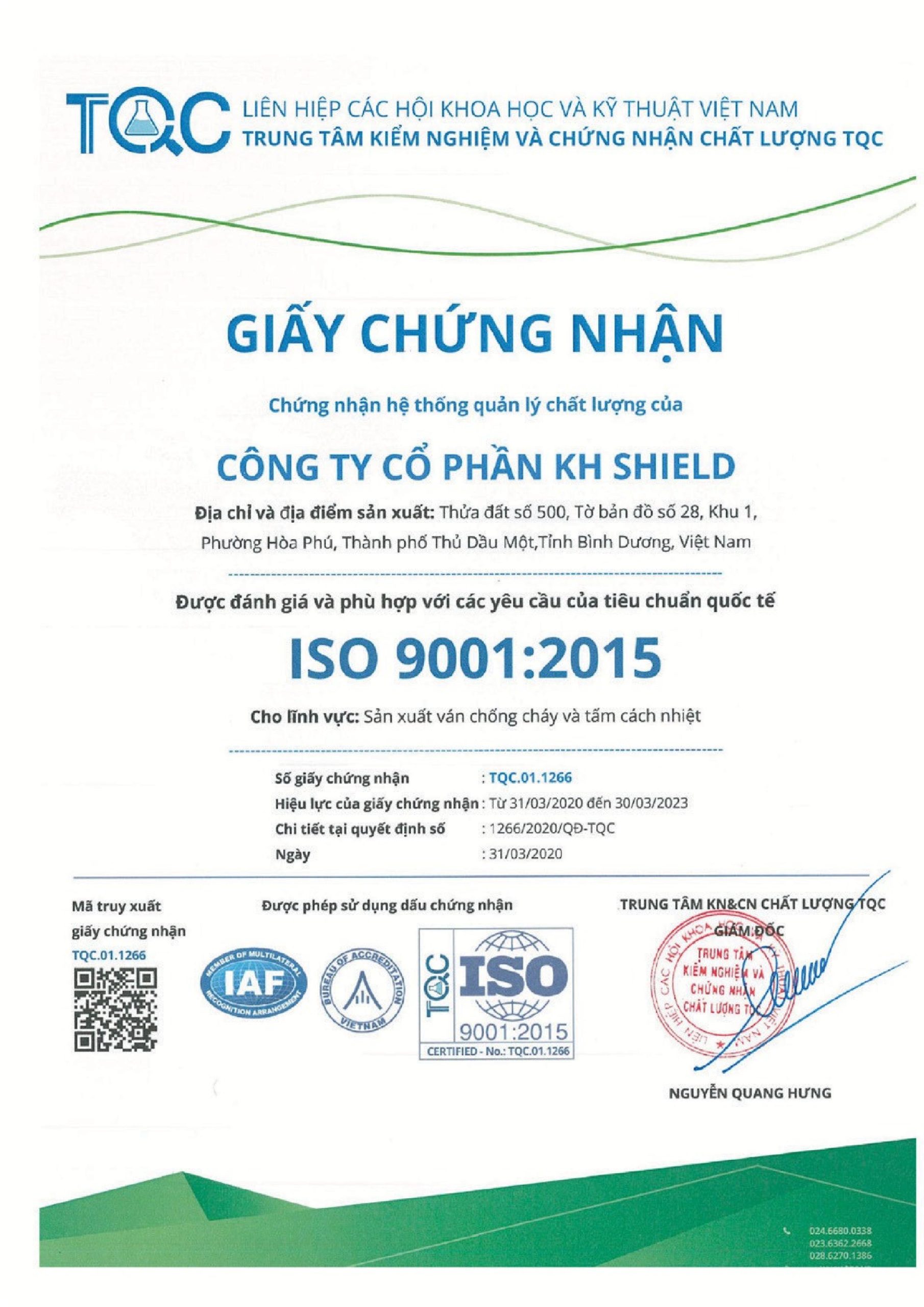

KH Shield takes pride in being a trusted partner with manufacturers of fire retardant, flame resistant, and insulation products. KH Shield's fire-resistant and insulation panels have achieved outstanding advantages in the field of fire-resistant material manufacturing.

| Types of fire-resistant and insulation materials commonly used today

In recent years, ongoing incidents of fire and explosions have caused extremely serious damage. Therefore, the top priority in construction is to find fire-resistant materials and effective fire protection solutions.

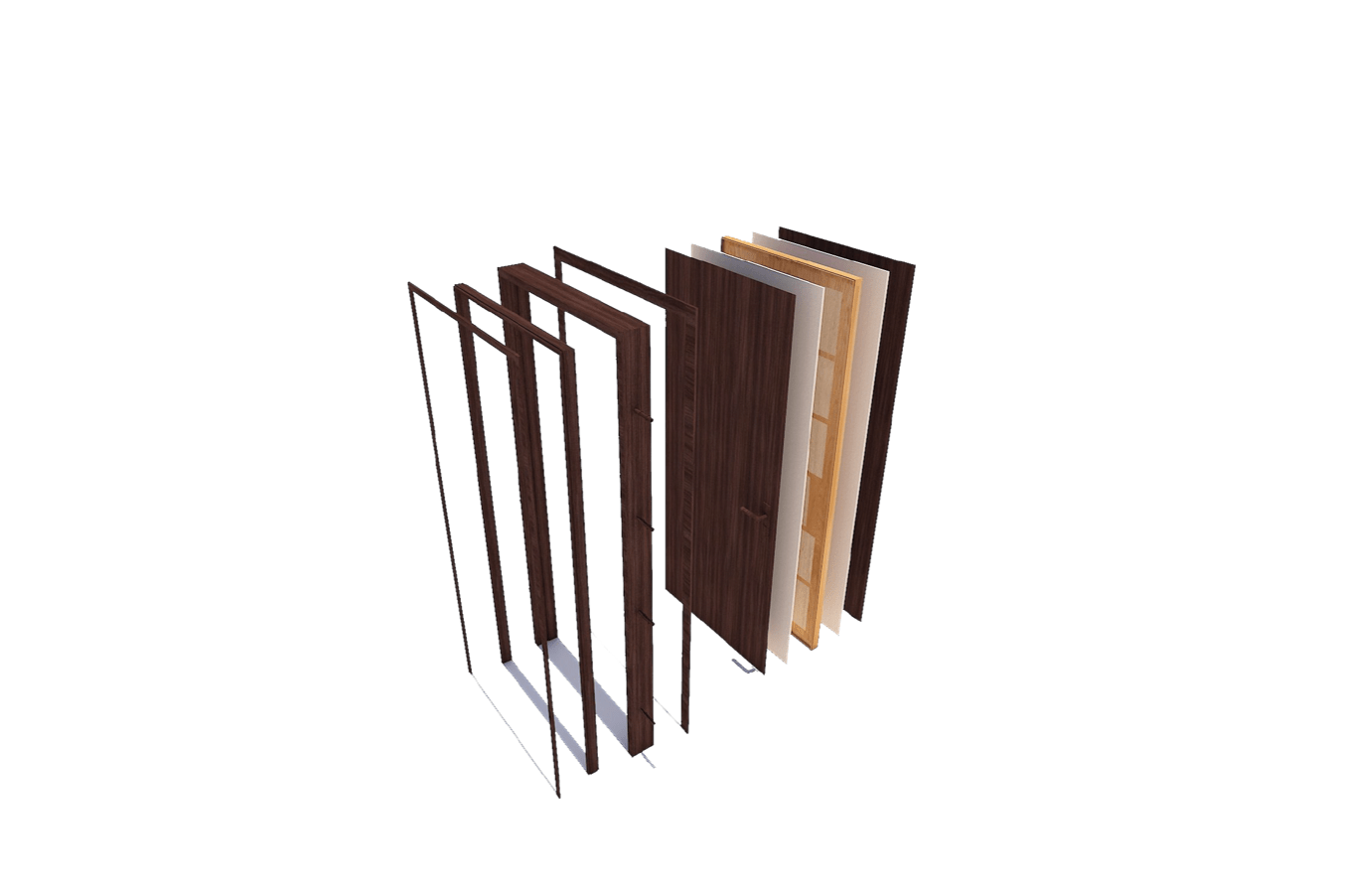

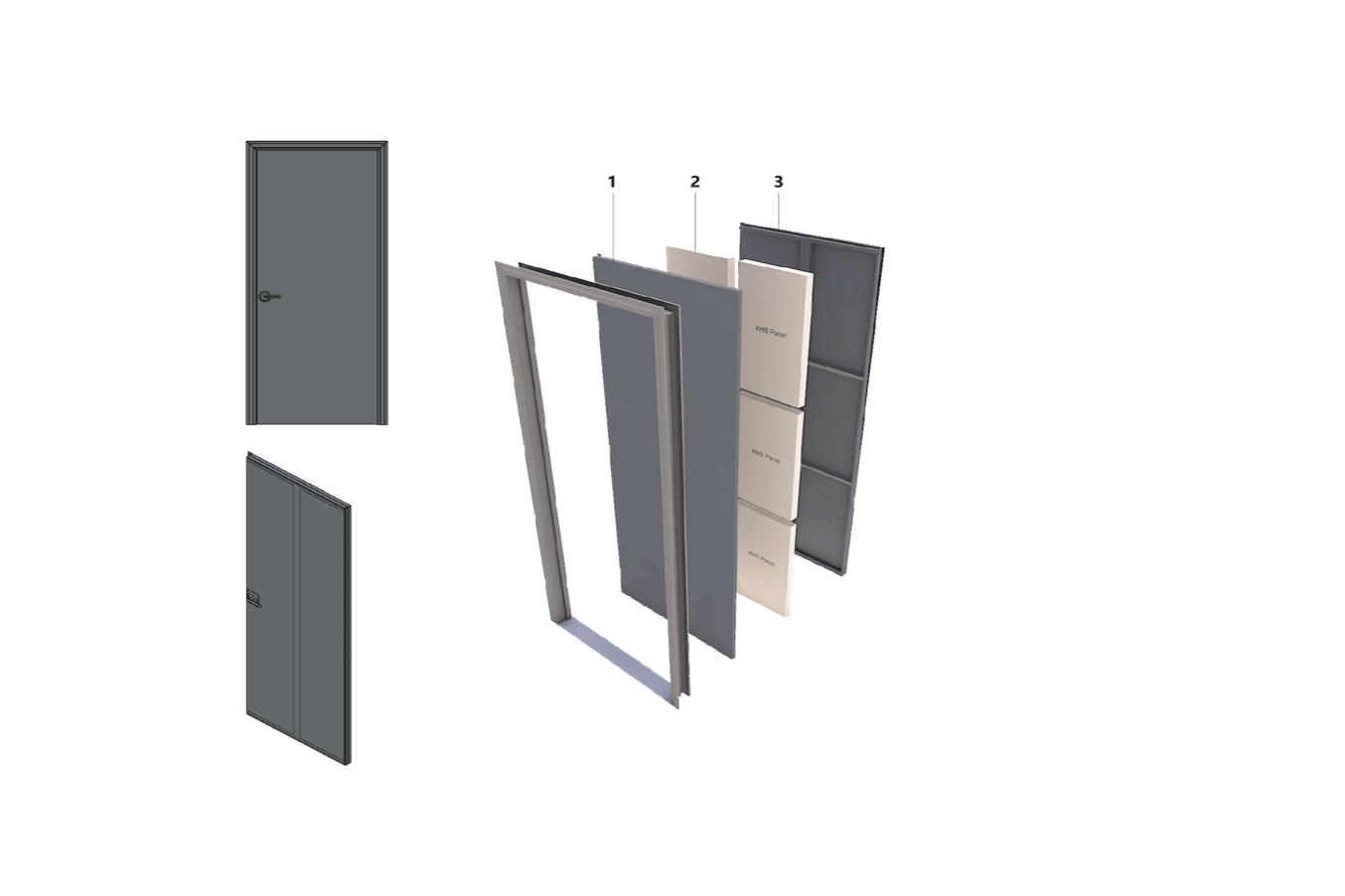

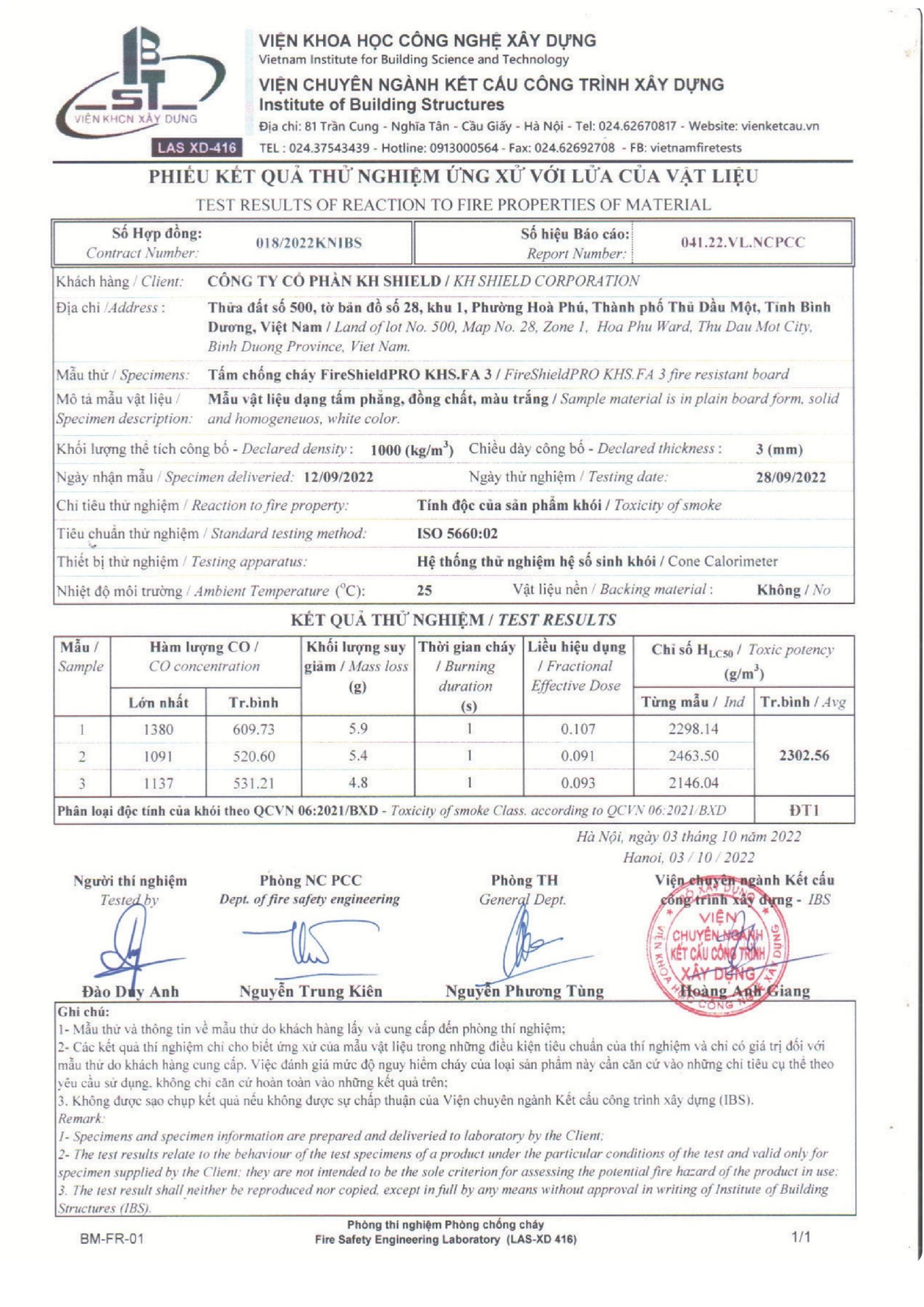

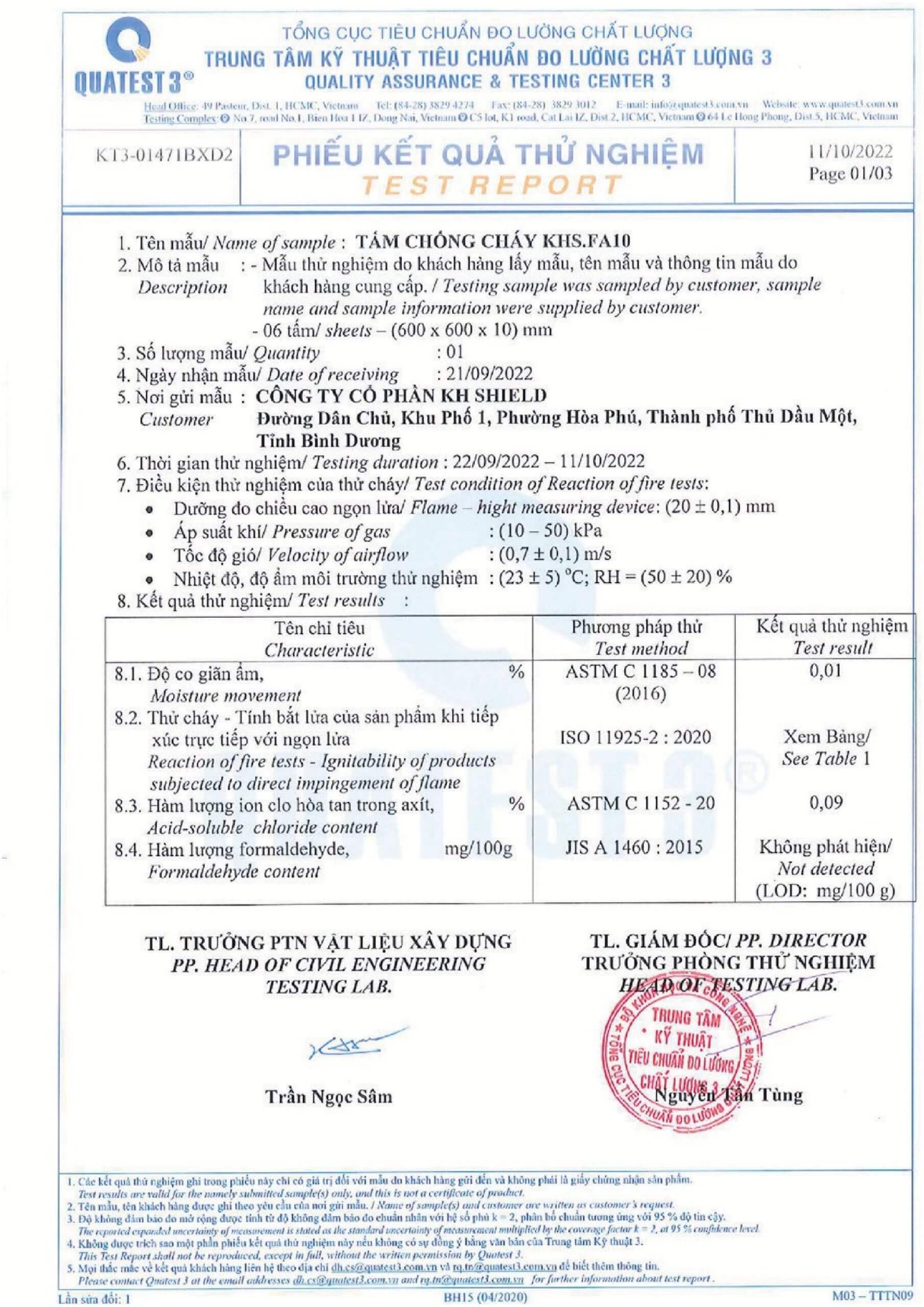

Fire-resistant panels Fire-resistant panels are one of the products used to prevent fire in many construction projects. Businesses can use these panels to create specialized fire prevention solutions for projects such as:

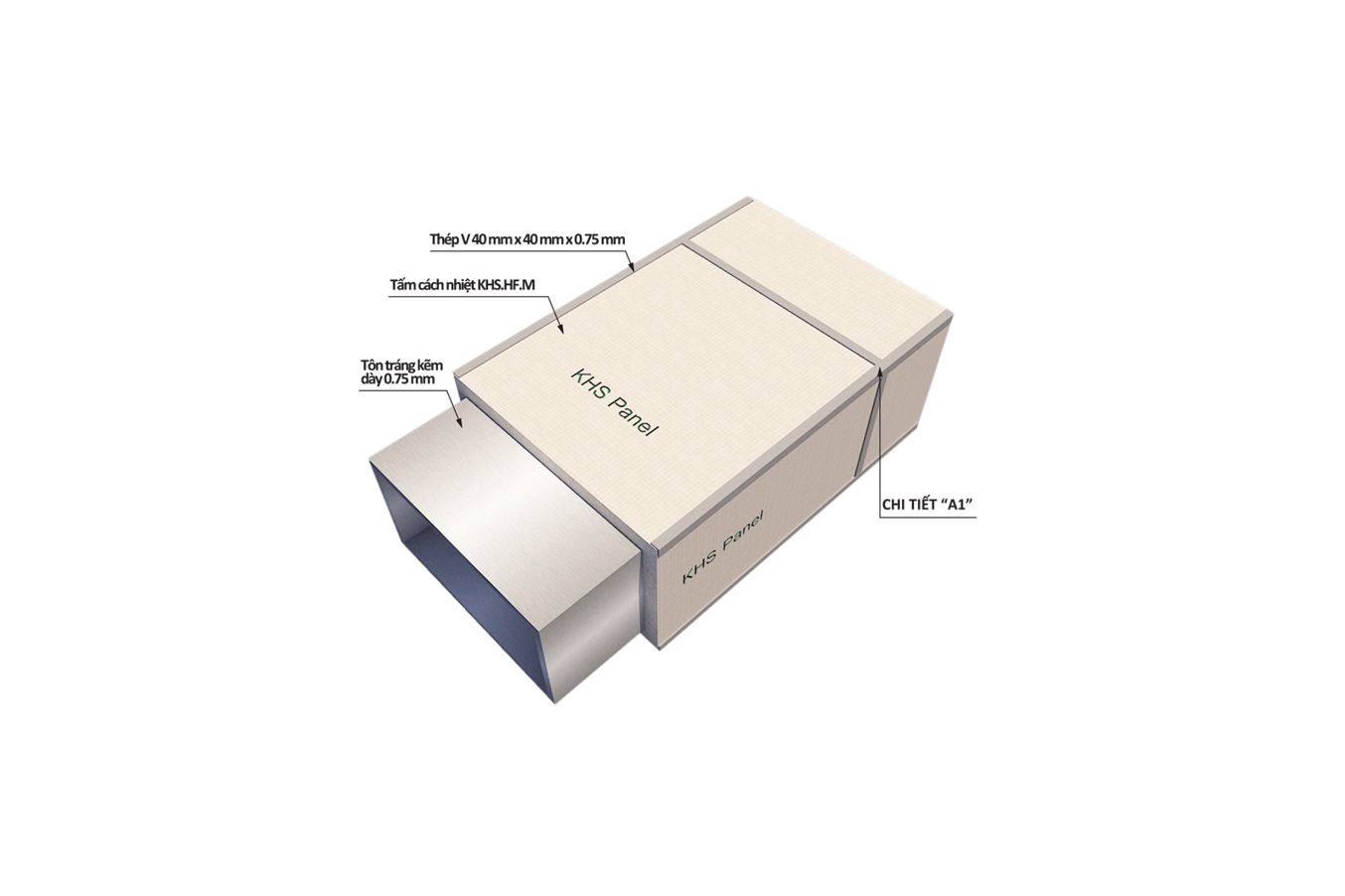

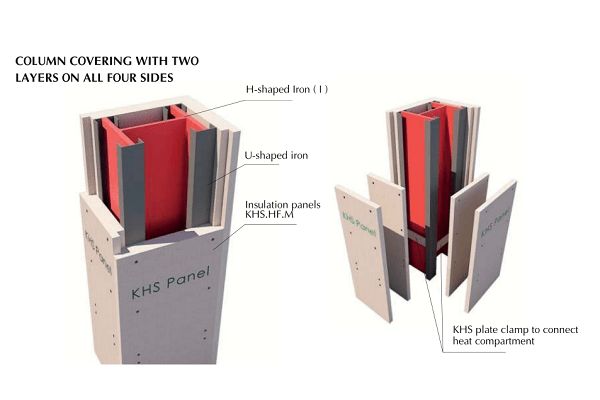

✅Fire-resistant doors, fireproof emergency exit door systems ✅Fireproof wrapping for air ducts ✅Creating protective layers for steel structures, beam cladding for fire-resistant columns.

Fire-resistant solution A water-based solution used to brush or spray on materials such as wood, curtains, etc., in homes to prevent fire spreading and slow down the combustion process in case of fire. Currently, KH Shield produces two types of fire-resistant solutions:

✅Fire-spreading prevention solution for MDF wood materials KHS.MFL ✅Fire-resistant solution for curtains, fabrics, and carpets KHS.FFL |

|

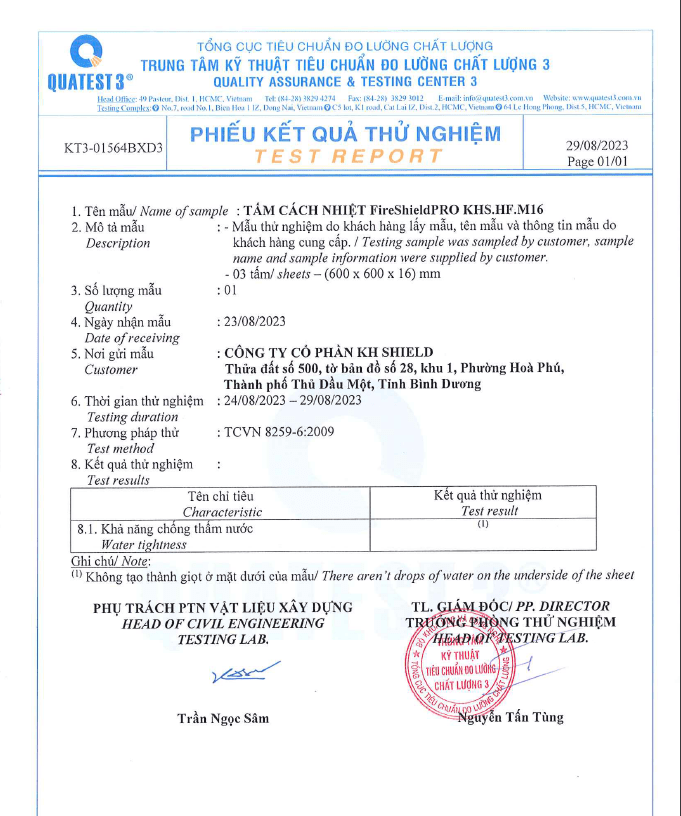

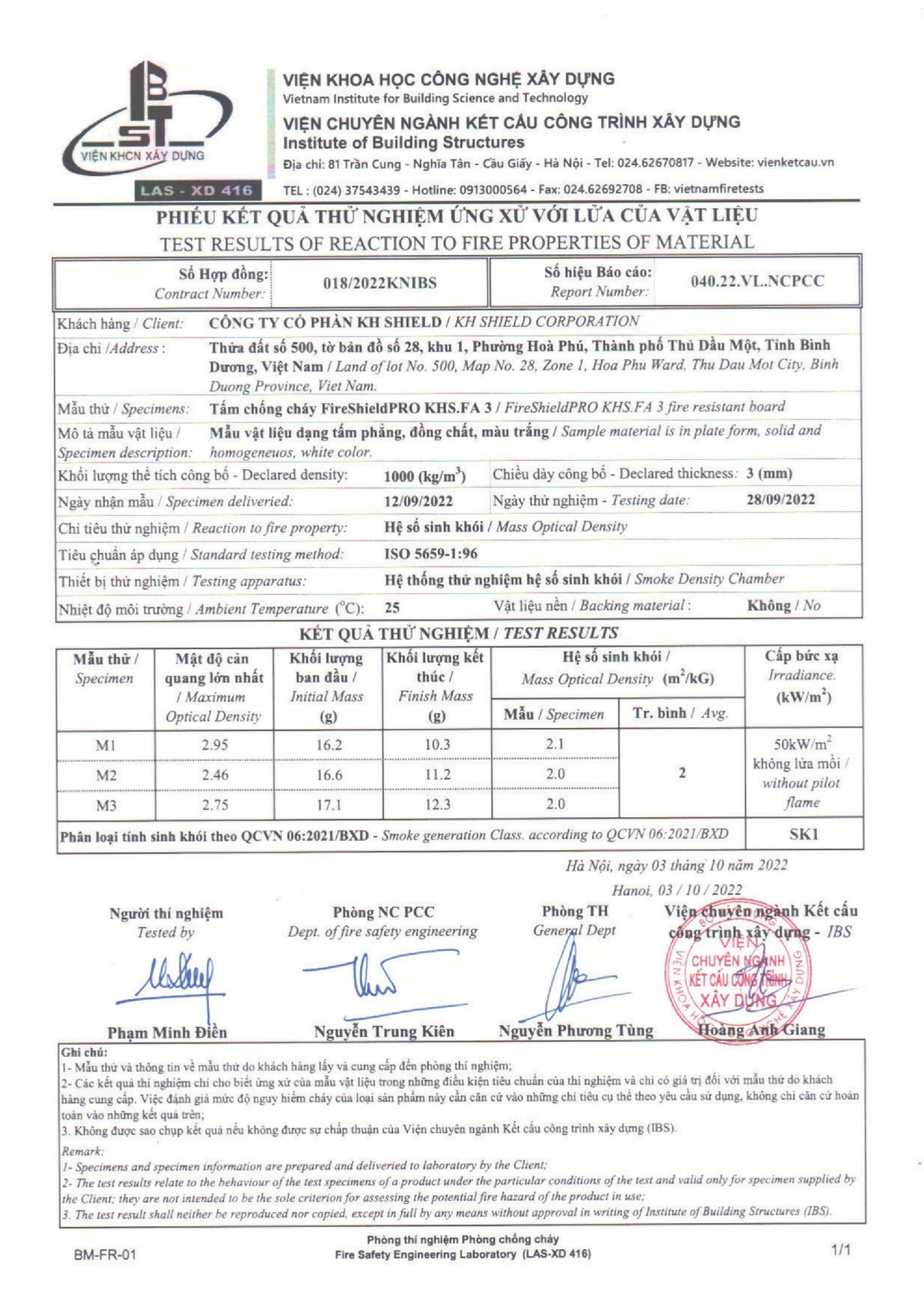

Fire and Insulation Resistant Panels

Fire Retardant Solution

OUR SOLUTIONS

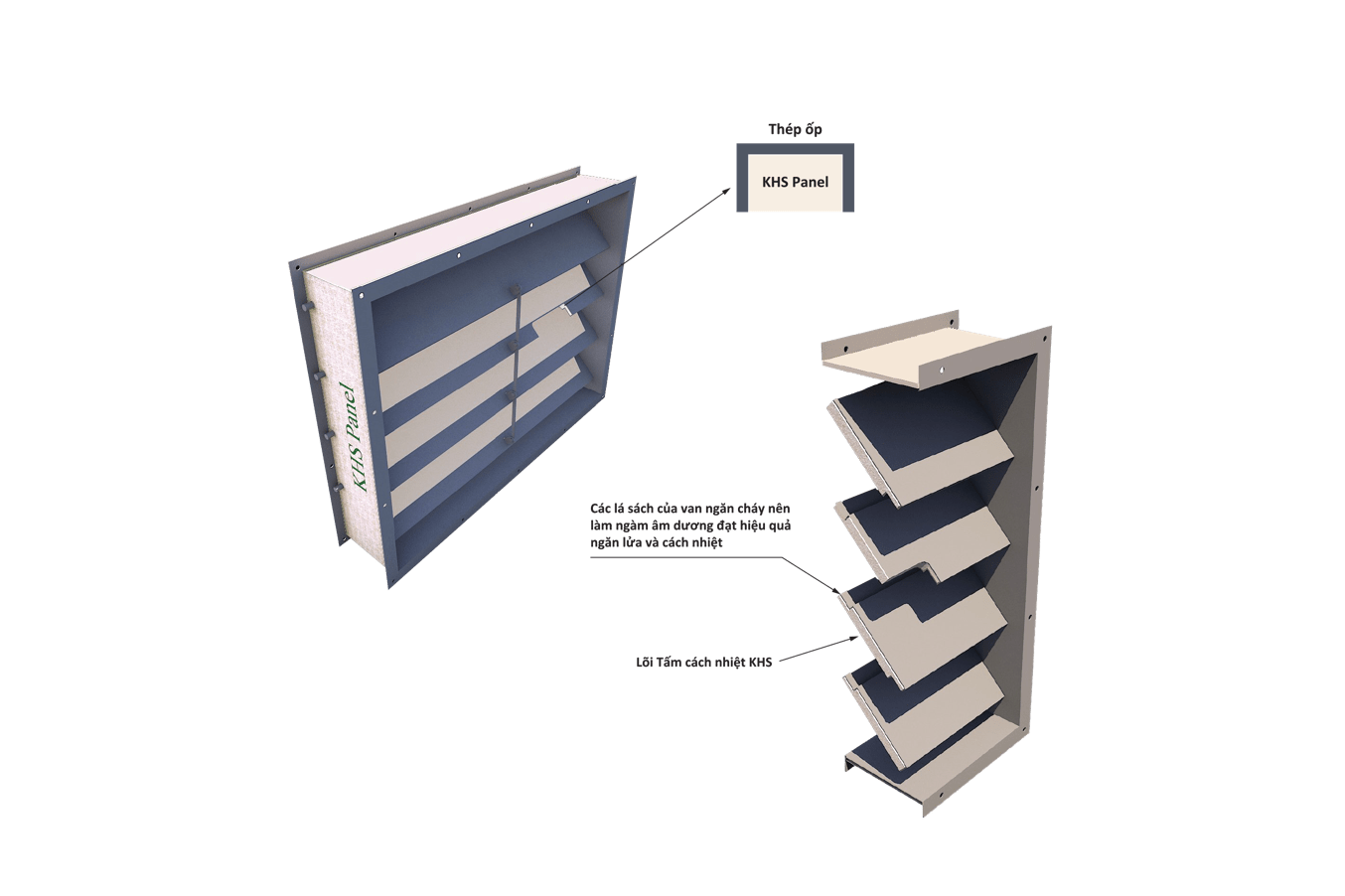

FIRE-RESISTANT DUCT STRUCTURE

STRUCTURAL PROTECTION WRAPPING

STRUCTURAL PROTECTION WRAPPING

COLUMN STRUCTURAL PROTECTION WRAPPING - BEAM STRUCTURE PROTECTION WRAPPING

Consultation on fire and explosion prevention solutions