Thematic

Explanation of the quality of fire prevention and insulation materials

The current construction materials market has more and more fireproof materials appearing. However, it is difficult for investors, designers and contractors to find an “omnipotent” material that can both meet the project structure and components; Just meets current fire safety standards.

Fireproof materials: Quality is still a big question

Fire and explosion prevention in buildings is always a hot spot in society. Most people are afraid and haunted by the scale and spread of fierce fires. Faced with that urgent situation, the introduction of fireproof materials has partly eased people’s worries and made construction works more solid.

Nowadays, we can easily come across some popular fire prevention structures and components used in everyday life such as: fire doors (wooden doors, steel doors, glass doors), fire partitions, air ducts. fire prevention, fire prevention elevator,…

It is undeniable that the above fireproof materials, when meeting quality standards and clearly tested by specialized authorities, will bring safety to surrounding people and improve quality. project value, limiting serious damage if unexpected incidents occur.

However, not all fireproof materials produced can perform their role well. Many unfortunate incidents have occurred even though the project was supposed to use fireproof materials for components and systems. This creates skepticism about the quality of fireproof materials, the ability of the construction team, and the trust in the design and contractor.

Faced with that reality, many laws have been established to guide and enforce regulations on fire prevention, as well as promulgate standards specifically for fireproof materials.

Standards for some types of fireproof materials today

Currently, the safety of each fireproof material is evaluated based on fire danger including: flammability, flammability, fire spread on the surface, ability to create smoke and toxicity.According to QCVN 06:2021/BXD, each type of fire prevention material will have different technical requirements.

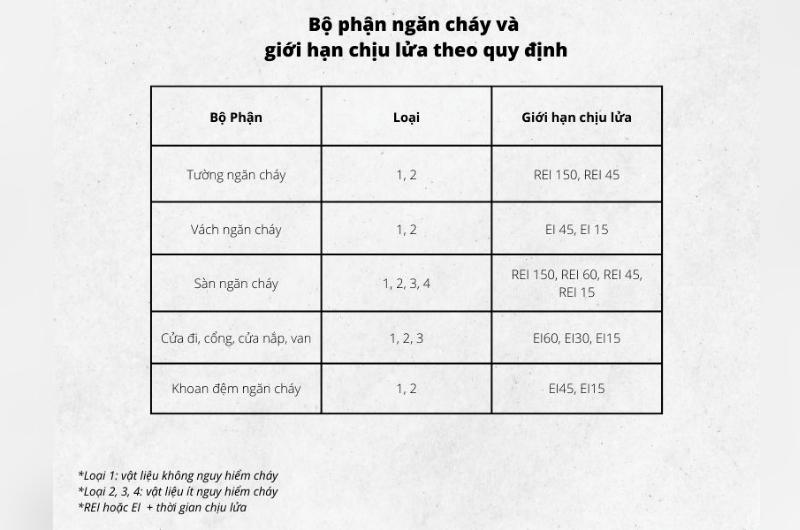

Especially in large civil works, it is also required that some areas and equipment must be equipped with fire-stopping materials such as: floor technical piping systems, fire gas transportation pipes, wall structures, … Below is the fire resistance time of some fire prevention components according to the latest 2022 law:

Depending on each part and constituent material, their prescribed fire resistance limits will be different

Below are more specific standards for some popular fireproof materials today:

NỘI DUNG BÀI VIẾT

Standards of fire partitions

Fire partitions must be inspected according to each design system, not the types of materials used to make fire partitions. Standards of fire partitions are determined based on the following factors:

- Thermal insulation: is the critical state of a fire-stop structure when the surface not exposed to fire increases on average to 140 degrees Celsius and at no point increases above 180 degrees Celsius.

- Fire resistance limit: is the time (in hours or minutes) from the start of the fire resistance test according to the standard temperature regime of the samples until one of the limit states of the structure and components appears ( loss of bearing capacity, loss of integrity, loss of thermal insulation).

- Sample integrity is damaged when: The sample system is broken or collapsed. Check with a cotton pad at the gaps, cracks or holes on the non-fire exposed surface of the sample system to see that a flame appears and burns stably. Form a hole that allows a 6mm gap gauge to pass through and move along the length of the hole by at least 150mm. Form a hole that allows a 25mm gap gauge to pass through. A stable burning flame appears on the non-fire exposed surface of the product sample systems for more than 10 seconds.

- To be considered a flammable structure, fire partitions must be made from special fireproof materials such as KH Shield insulation panels.

- Fire resistance limits (calculated in minutes) of partitions are usually around 15 minutes, 30 minutes, 45 minutes, 60 minutes, 90 minutes, 120 minutes and 150 minutes.

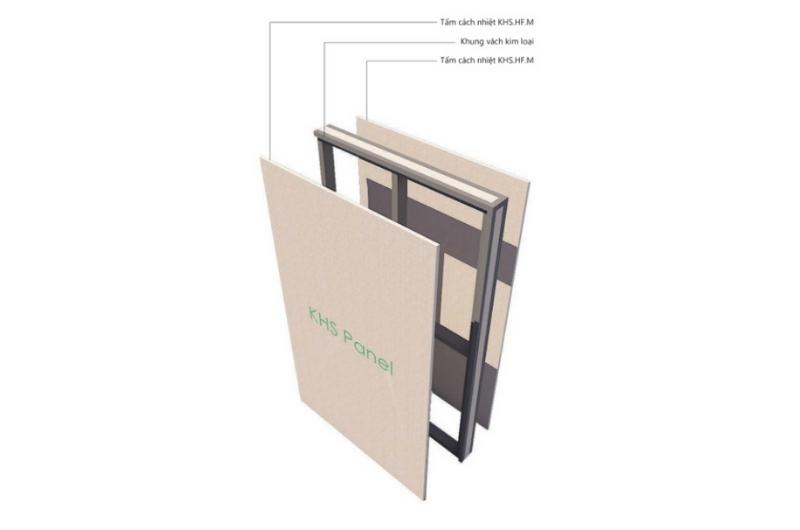

Structure of fire partition when applying KH Shield panels

Steel fire doors

According to regulations in TCVN 9383:2012, standard fire doors must fully meet the following criteria:

- Thermal insulation ability: the product must prevent heat from smoke, flame, gas, etc. for a minimum of 15 minutes and a maximum of 120 minutes.

- About manufacturing materials

– Windows, doors, and fire partitions between rooms must be made from materials that can withstand fire for at least 45 minutes.

– For fire doors installed in apartments and high-rise buildings, they must be made from materials with good fire resistance for a minimum period of 45 minutes, and must be equipped with an automatic closing mechanism. when a fire occurs. - Regarding size and thickness of the door:

– The standard size of fire doors is 1800 – 3000 mm high, 800 – 1200 mm wide.

– Fireproof doors must be equipped with steel wings 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm or 2.0 mm thick.

– The thickness of the fireproof door must be between 40 – 50 mm.

What is the optimal solution for current fireproof materials?

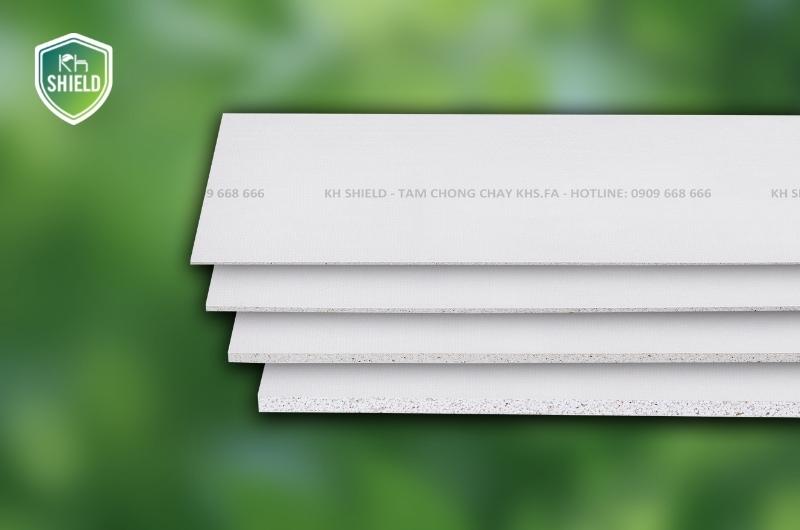

The increasing demand for fireproof materials means the emergence of a variety of solutions for the above fireproof materials. In particular, the KH Shield series of fireproof panels and insulation panels is considered the most typical solution for fireproof materials on the market today. The following outstanding advantages are the factors that create “score” quality for fire safety buildings:

- Non-flammable, no smoke, no toxins: Smoke in a fire contains many active particles, vapors, toxic gases,… that affect human life. Thanks to FireShieldPRO technology, KH Shield’s product series completely solves the above problems, helping fireproof materials to prevent fierce flames from invading for a long time, without generating smoke or toxins. .

- 3 hours of use when exposed to fire at 1000°C: Because it is made from carefully selected agricultural by-products along with adhesive materials and advanced production technology, it provides the ability to prevent the spread of fire. effectively.

- Durable in wet environments: Tested according to US ASTM standards, the moisture expansion of KH Shield panel products is from 0.01%, showing that in a humid environment, the panels still retain their inherent performance and function. no change in volume, helping construction components stay intact and providing peace of mind for the project as well as users.

- Environmentally friendly green materials: From agricultural by-products, imported raw materials are safe, do not contain toxic substances, and the production process is not baked; KH Shield panels completely bring peace of mind when used for projects.

- Meets all fire protection testing standards: To be considered a breakthrough product for fireproof wall solutions, KH Shield panels have undergone strict testing and meet all fire protection standards.

The KH Shield panel product series can be effectively applied to today’s popular fire protection solutions

Above is some information to keep in mind when producing and choosing fireproof materials. In general, we need to choose solutions that ensure quality and meet fire safety standards.

Above all, we need to understand the characteristics and properties of each type of fireproof material. to make the right choices for your project, meet the requirements of construction quality, reduce damage when a fire occurs, as well as increase the durability of the project and save costs. maintenance.

Besides, to clarify more about current fire safety standards, specifically the latest standard QCVN 06:2021/BXD, as well as the application of KH Shield fireproof panels for management materials. today’s leading management; On March 18, 2022, the conference Wanting to Be Safe – Removing difficulties in applying QCVN 06:2021/BXD – New fire prevention applications of KH Shield panels will take place at ADORA Phu Nhuan, promising to bring a lot of information Useful news for businesses. To register to attend the event, please contact 0908391709 (Ms. Ha) or 0888777738 (Mr. Duy). KH Shield is pleased to welcome you.

Update the latest topic

Update highlights

Consultation on fire and explosion prevention solutions