Thematic

MgCl₂ vs. MgSO₄: The Battle for Durability in Fire Protection Systems

🔥 MgCl₂ vs. MgSO₄: The Battle for Durability in Fire Protection Systems

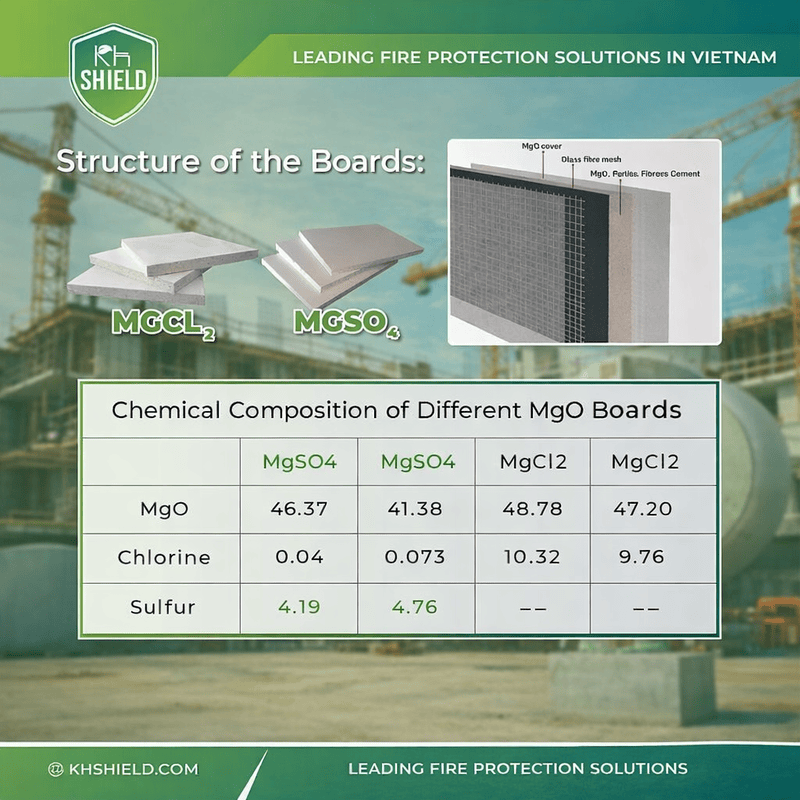

There are currently two types of Magnesium Oxide (MgO) fire-rated boards on the market.

They may look similar on the surface, but the long-term consequences after two years of use are worlds apart.

NỘI DUNG BÀI VIẾT

🔴Type 1: Salt-Based Boards (MgCl₂)

- Mechanism: Absorbs moisture from the air → Surface condensation (“board sweating”) → Saline liquid drips down and corrodes steel ducts and hanger rods.

- Consequences: Severe corrosion of the air duct system, material deterioration, risk of structural failure, and loss of fire-resistance performance.

🟢Type 2: KH Shield Boards (MgSO₄)

- Composition: Formulated with Magnesium Sulfate (MgSO₄) and FireShieldPRO® technology.

- Mechanism: Non-hygroscopic, with chloride content ≤ 0.1% (in accordance with ASTM C1152-04).

- Result: NON-CORROSIVE TO METAL — effectively protects the galvanized coating of air ducts, keeping them clean, intact, and corrosion-free over time.

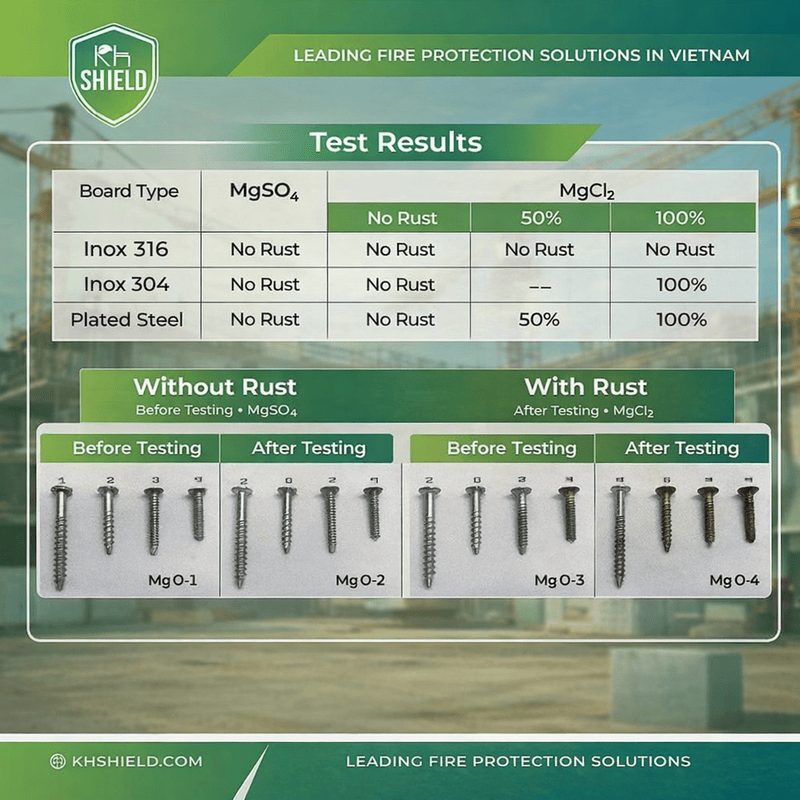

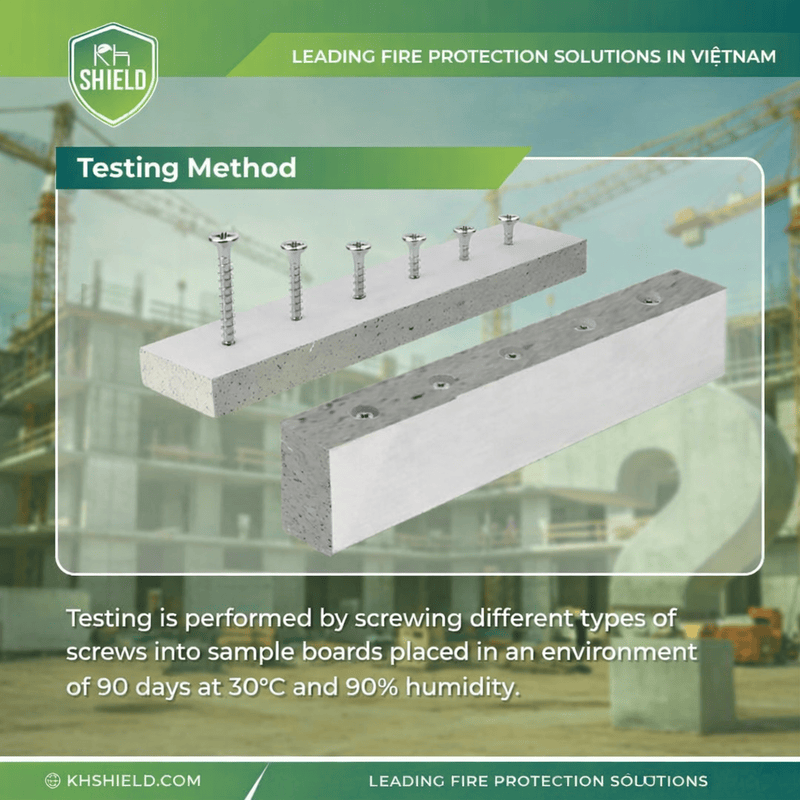

🧪CLIMATE CHAMBER TEST RESULTS (30°C – 90% RELATIVE HUMIDITY)

Based on comparative data derived from BRANZ (New Zealand) research:

- ❌ Screws installed into MgCl₂ boards:

Corrosion observed on 50%–100% of the surface area. - ✅ Screws installed into KHS boards (MgSO₄):

NO CORROSION DETECTED.

💡 ADVICE FOR CONTRACTORS

Don’t be tempted by short-term savings when choosing salt-based boards.

Future maintenance, warranty claims, and duct replacement costs can be up to 10 times higher than the initial material cost.

🛡️Choose KHS.HF.MPro14 (14 mm) — Choose Absolute Peace of Mind.

The product has been:

-

Fire-tested for 132 MINUTES at IBST, and

-

Proven non-corrosive through BRANZ research.

📩 Contact KH Shield today to receive test samples for on-site corrosion evaluation.

Update the latest topic

Update highlights

Register for consultation

Consultation on fire and explosion prevention solutions