Thematic

The risks of using low-quality fire-resistant materials

Fire-resistant material is a core element in providing fire prevention and insulation capabilities for the entire fire-fighting system. The use of low-quality fire-resistant materials can pose various hidden risks that affect both property and human lives. Currently, the government has also become stricter in issuing regulations regarding the quality management of fire-resistant materials in construction projects

The current demand for the use of fire-resistant materials

Using low-quality fire-resistant materials can lead to serious fire consequences.

Protecting property and human lives.

In modern life, the risks of fire and explosions are ever-present in places such as apartment buildings, commercial towers, manufacturing workshops, or factories. This not only threatens property damage but also impacts human health and lives. Consequently, the demand to enhance fire resistance through fire prevention and insulation solutions continues to rise. Fire-resistant materials have consequently seen increased investment in research and development.

Currently, fire prevention and insulation solutions have become more familiar and are being used more extensively in construction projects. Steel fire doors, fire-resistant rolling doors, and fire-resistant duct solutions are commonly seen as alternatives to regular doors, traditional ducts in ventilation systems, and fire-resistant steel coatings in the structural systems of buildings, respectively.

These are all fire prevention and insulation solutions that employ fire-resistant materials to overcome the limitations of traditional products’ fire resistance capabilities. As a result, fire-resistant materials are gradually proving their importance and strong impact on construction projects, enhancing protection for both people and property.

Strict state fire safety regulations.

Furthermore, the state has established numerous fire safety regulations, such as the National Technical Regulation QCVN 06:2021/BXD and Decree No. 136/2020/NĐ-CP, which impose strict compliance requirements on construction projects. This has posed challenges for construction companies and material suppliers alike. Consequently, businesses are increasingly seeking new fire-resistant materials that can meet these regulations.

In practice, using fire-resistant materials that meet state standards ensures safety and improves the quality of fire prevention and firefighting systems, preventing property damage and loss of life.

Current fire-resistant materials market situation.

The present fire-resistant materials market is quite diverse, with various types and designs available. However, finding a product that complies with state regulations is not an easy task. To introduce fire-resistant materials to the market, businesses need to achieve quality certifications for each product through testing at authorized agencies.

Fire-resistant materials and the consumption market in our country.

Some prevalent types of fire-resistant materials on the current market include:

Sprayed Fire-Resistant Material (SFRM)

These are materials that are typically applied as coatings, such as cement and gypsum. Sprayed fire-resistant materials are usually used on steel and metal surfaces in general. However, a drawback of this material is its potential to release toxic substances that can affect human health during application.

Surface Coating Fire-Resistant Material

This is a common type of material, like fire-resistant paint for steel components. When exposed to fire, the coating expands and creates a protective space between the fire and the steel structure, enhancing fire protection. Additionally, this option can also work well on wood materials.

A common drawback of this type of fire-resistant material is its limited aesthetic appeal. With each coat applied, the thickness of the surface significantly increases.

Fire-resistant material is a fundamental element in providing fire prevention and insulation capabilities for the entire firefighting system. The use of low-quality fire-resistant materials can pose various hidden risks that affect both property and human lives. Currently, the government has also issued regulations regarding the quality management of fire-resistant materials in construction projects.

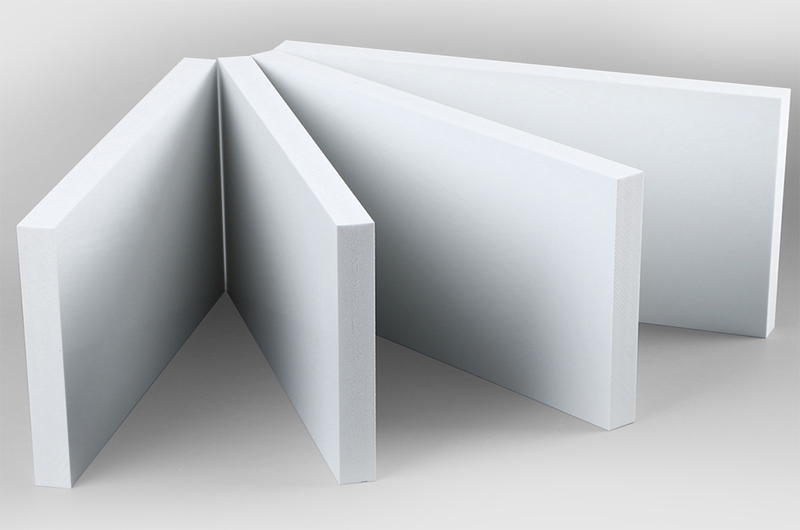

Fire-Resistant Panels

Fire-resistant panels are used in fire prevention and insulation solutions to control temperature and prevent fire spread. Depending on specific needs and usage purposes, manufacturers can offer products with suitable thickness and dimensions. Additionally, high-quality fire-resistant panels can also provide waterproof, noise-reducing, and termite-resistant properties.

On the downside, fire-resistant panels are modern products with various advanced features, thus their cost is considerably higher compared to other types of products.

Low-quality Fire-Resistant Materials and Potential Hazards

The potential hazards of using low-quality fire-resistant materials

When using low-quality fire-resistant materials, in the event of a fire, people will face potential dangers such as:

- Fire Spread: Poor-quality fire-resistant materials can inadvertently fuel larger fire spread.

- Generation of Black Smoke: Some low-quality fire-resistant materials often produce black smoke due to their specific properties. This poses a health risk to humans as well as challenges for evacuation.

- Toxic Emissions: Certain types of low-quality fire-resistant materials can release toxic emissions when burned or even under normal conditions.

- Environmental Harm: Apart from endangering people, low-quality fire-resistant materials can also contribute to environmental pollution, from the production stage to decomposition and recycling.

Low-quality fire-resistant materials not only harbor risks that impact human health and lives but also fail to meet the fire safety standards established by the government. Individuals should carefully consider their choices before deciding on a suitable type of fire-resistant material.

Update the latest topic

Update highlights

Consultation on fire and explosion prevention solutions