Thematic

Fire barrier valve solutions utilize fire barrier panels and KH Shield insulation panels

The fire barrier valve solution is one of the crucial components in the current ventilation system. With significant advancements to provide superior fire prevention capabilities, the fire barrier valve has gradually become an indispensable choice in the fire prevention and firefighting systems of any construction project and residence.

State regulations for standard fire barrier valves

The fire barrier valve solution meets the QCVN 06:2021/BXD standard for fire safety.

In 2021, the Ministry of Construction issued the National Technical Regulation on Fire Safety for Buildings and Structures – QCVN 06:2021/BXD, which requires fire barrier valves used in air distribution systems to meet minimum fire resistance time standards based on fire resistance criteria.

These fire resistance criteria applied to fire barrier valves include integrity (E) and insulation (I). However, in certain installation positions, fire barrier valve solutions may only need to achieve integrity (E). In fire resistance testing of the barrier valves, the values of integrity (E) and insulation (I) are determined as follows:

- Integrity (E): This is the time interval during which the test specimen exhibits phenomena such as collapse, surface instability without flame exposure, and the appearance of openings wider than 6mm and deeper than 150mm or openings wider than 25mm.

- Insulation (I): This is the time interval during which the test specimen experiences a temperature increase of 140K compared to the initial average temperature on the non-exposed face or an additional 180K at any location.

Current selection of fire barrier valve solutions

Three considerations when selecting a fire barrier valve solution

To choose a fire barrier valve solution that aligns with usage needs while ensuring compliance with prevailing fire safety standards, individuals can consider the following factors:

Selecting fire barrier valves meeting the EI standard for fire resistance

Utilizing fire barrier valves meeting the EI standard as specified in QCVN 06:2021/BXD will provide optimal fire resistance and insulation capabilities for the ventilation system. Additionally, this choice helps businesses avoid concerns regarding the standards of fire-resistant materials currently being enforced.

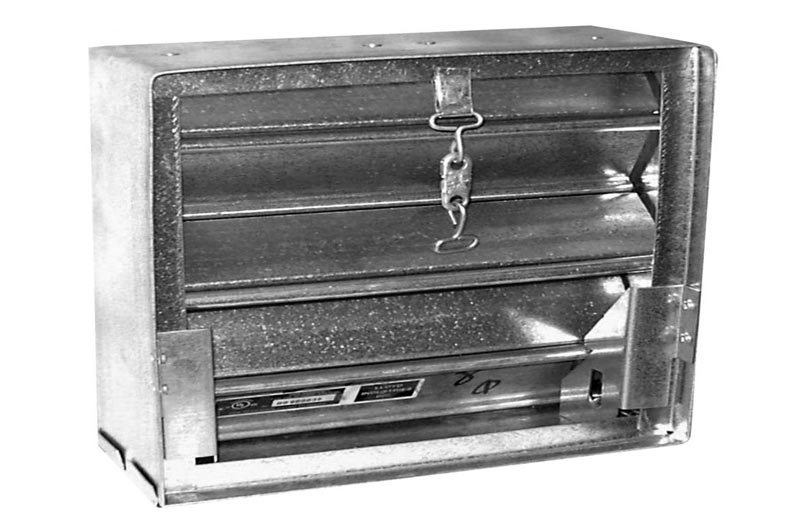

Choosing automatic fire barrier valves

Among the various types of ventilation valves available in the market, fire barrier valves employing a fusible link with an automatic closing mechanism are a suitable choice for both general fire protection systems and ventilation systems in particular.

In case of a fire outbreak, the fusible link within the automatic fire barrier valve will melt and trigger the closing mechanism. This action effectively prevents the spread of fire and smoke from the fire location. Meanwhile, fire-resistant materials applied within the fire barrier valve ensure insulation and prolong evacuation time for occupants inside.

Opting for fire barrier valves incorporating quality fire-resistant materials

The core fire-resistant material in the fire barrier valve significantly contributes to its fire resistance and insulation capabilities. Hence, the fire-resistant material used in the fire barrier valve should be sourced from reputable suppliers and adhere to all relevant state-certified standards.

The KH Shield insulation board applies to fire barrier valves

Fire Barrier Valve Solution Utilizing KH Shield Fireproofing and Insulation Panels

The KH Shield insulation board is a fire-resistant material widely applied in various fire prevention and insulation solutions, notably in fire barrier valve solutions for ventilation systems.

The KHS.HF.M insulation board and KHS.FA fireproofing board are used as the core of fire barrier valves, offering several exceptional advantages:

- Non-flammable: Prevents the fire-exposed surface of the valve from catching fire and spreading to other areas.

- No production of black smoke: Limits the formation of black smoke and contributes to smoke prevention for occupants during a fire.

- 3-hour usability at 1000°C environment: In temperatures up to 1000°C, the KH Shield fire barrier and insulation panels can provide continuous protection for 3 hours. This ensures the fire-exposed surface of the valve remains intact at lower temperatures, even during an ongoing fire on the other side.

The fire barrier valve solution incorporating KHS.HF.M insulation boards and KHS.FA fireproofing boards is structured as follows:

- For EI 30-minute standard: KHS.FA6 fireproofing board + KHS.HF.M16 insulation board + KHS.FA6 fireproofing board.

- For EI 45-minute standard: KHS.FA6 fireproofing board + KHS.HF.M20 insulation board + KHS.FA6 fireproofing board.

- For EI 60-minute standard: KHS.FA6 fireproofing board + KHS.HF.M24 insulation board + KHS.FA6 fireproofing board.

- For EI 90-minute standard: KHS.FA10 fireproofing board + KHS.HF.M24 insulation board + KHS.FA10 fireproofing board.

The fire barrier valve solution employing KHS.HF.M insulation boards and KHS.FA fireproofing boards is the optimal choice for ventilation systems, offering superior fire resistance and insulation capabilities. This selection also aligns with state regulations ensuring fire safety for construction projects.

Update the latest topic

Update highlights

Consultation on fire and explosion prevention solutions